As Blacklidge’s new Product Management Director, I have the privilege of bringing innovative asphalt products to market. While I champion all asphalt innovations, I am particularly excited about the emergence of recycled asphalt products, such as Blacklidge’s ReGen®. However, there is a disconcerting trend in the industry that is somewhat resistant to embracing sustainable products, such as RAP and RAS. This begs the question:

How can we ensure the sustainability of our sustainable asphalt products?

In 2016, I penned an article in Texas Asphalt Magazine about sustainability in the asphalt industry. In this piece, I made the argument that asphalt sustainability efforts—particularly those in Texas—were on the decline. Two years later, that argument is still valid nationwide.

The National Asphalt Pavement Association’s most recent report on the matter, Asphalt Pavement Industry Survey on Recycled Materials and Warm Mix Asphalt Usage, suggests that the growth trend with respect to the use of RAP in asphalt mixes has remained flat over the last three years. NAPA’s study also concludes that the use of RAS is falling at a precipitous rate from years past.

Despite NAPA’s findings that using RAP and RAS in asphalt mixtures saved the industry more than $2.2 billion (!), many state DOTs have placed limits on the allowable volume of recycled materials included in asphalt mixes. These limitations are due to the perception that high levels of RAP and RAS are responsible for premature failures. Not so, my colleague Grover Allen, P.E., Ph.D. points out in his blog post. For example, RAP usage in Japan is significantly higher compared to the U.S. yet pavement performance in Japan is outstanding (97.7 percent of RAP sections are meeting serviceability requirements). If the data proves that RAP itself is not the root of the problem, then what is?

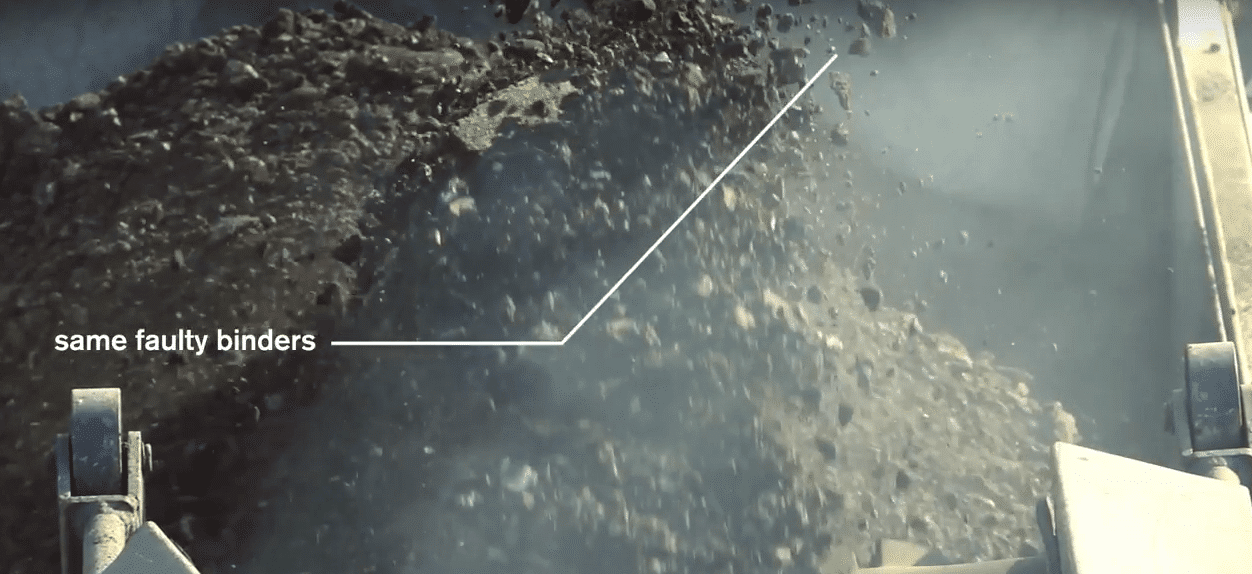

Echoing the sentiment of my colleague, Dr. Allen, low quality binder is the number one reason we are seeing high rates of premature failure with RAP usage in the U.S. In order to reverse this trend, hot asphalt mix designers should consider including additives like Blacklidge’s ReGen. Regenerative products, such as ReGen, offer mix designers an opportunity to verify that long-term performance parameters can be achieved while pushing the limits of how much reclaimed asphalt can be included.

Going back to my original question: How can we ensure the sustainability of our sustainable asphalt products? A step in the right direction would be embracing regenerating modifiers so that we could use more RAP and RAS in our asphalt mixes, resulting in more environmentally (and economically) positive outcomes.