When you think about recycling, what do you picture? Most people think about items such as a plastic bottle or an aluminum can that looks, feels, and functions like new, with a label saying it’s made with recycled material.

Those of us in the asphalt industry may think of reclaimed asphalt pavement (RAP). Asphalt pavement recycling has been happening for decades. It is not uncommon to see various aspects of this practice referred to as either “recycling” or “reclaiming,” depending on the source. For example, MS-4 – AI’s Asphalt Handbook devotes chapters to Reclaimed Asphalt Pavement, Hot-In-Place Recycling, Cold-Mix Recycling, Cold In-Place Recycling, and Full-Depth Reclamation. NCAT’s HMA Materials, Mixture Design, and Construction Manual devotes sections to Hot Recycling, Hot Mix Asphalt Recycling, Hot Surface Recycling, Structural Recycling, and Cold Mix Recycling. As a final example, MS-19 – AI’s Basic Asphalt Emulsion Manual has an entire chapter on Asphalt Pavement Recycling.

According to these references, it would seem that our industry has duplicated the success of material reuse common in various other industries by implementing methods of upgrading RAP so that it looks, feels, and functions like new. To test this theory, let’s consider a couple of definitions per Merriam-Webster:

Recycle – (1) To return to an earlier point; (2) To return to an original condition, so that operation can begin again.

Reclaim – (1) To obtain from waste product or by-product; (2) To restore to a previous natural state.

Those familiar with our industry’s use of RAP should pause at this point. This is because there is a clear discrepancy between our terminology and our practices, particularly in light of other industries’ practices – others upgrade or restore waste and thereby create a superior final product; our industry downgrades the final product by virtue of failing to enhance the waste. For example, look at urbanite. This waste concrete is transformed into a durable product like flagstone and used for patios, walkways, fire pits, and more. The expectation is that urbanite functions and continues to perform like new alternatives.

Currently, our industry allows reprocessed waste (mostly failed asphalt pavement that contains highly oxidized and brittle binder) to be placed back into new mixtures in diluted form. Industry standards typically allow about 20% RAP in the new pavement mixture. In certain cases, an even higher percentage of RAP may be permitted, and the only requirement is typically that it must be combined with a “softener” or a softer grade of asphalt. In other words, the assumption is that if we minimize and mask the inferior quality of waste asphalt that is combined with new asphalt, it won’t cause too big of a problem. There is nothing wrong with this approach…if it actually works.

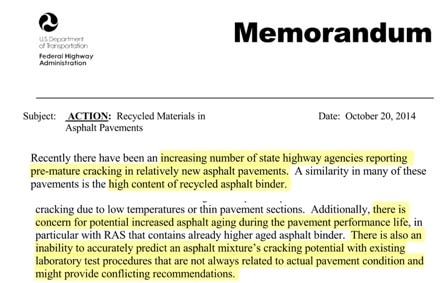

In 2014, many of you may recall receiving a memo from the Federal Highway Administration (FHWA) countering this assumption:

This FHWA memo and the industry findings that preceded it served as a wake-up call for me. For one, various test procedures that our industry experts previously relied upon to predict cracking performance were promptly deemed unreliable, yet many of them are still being utilized today. Secondly, the long-held belief that diluted percentages of RAP combined with “softeners” or soft binder is sufficient to yield a durable roadway was shattered by the reality of the situation, yet these practices continue today. Many of our best experts responded by developing and implementing new test procedures that will more accurately predict performance. This is still a work in progress. What we must be cognizant of during this process is that we don’t continue to utilize failing materials created by flawed teachings to calibrate more tests that won’t accurately predict performance. While we have the right idea to reuse RAP in some way, we aren’t using it the right way to optimize road life. Let’s forget for a moment all of the reasons why it is a great idea to reclaim and reuse waste product, i.e. reduce initial raw material consumption, initial cost, and landfill space, and instead consider the broader picture. If waste materials are added to new asphalt without properly considering the road’s aging process and life cycle costs, then we have not recycled anything. We are causing the reverse effect: more waste.

One of the best examples of the problem getting out of hand is found in recent challenges faced by the Taiwanese government. After multiple iterations of RAP usage to overcome decades of budget constraints, the state has finally recognized that benefits were short-lived. Impacts of the extremely deteriorated quality of RAP asphalt – particularly with respect to a second RAP cycle and beyond (RAP that previously contained RAP) – include a series of successive premature failures in pavements, which has subsequently led to more intensive RAP screening and even banning RAP from use in paving mixtures. (Yang, S.H. (2017). Hot Recycling Technologies: Experiences and New Challenges in Taiwan, AAPT).

Even when so-called “recycling agents” and “rejuvenators” have been utilized in the past, a lack of performance standards relative to these potential solutions have led to their failure as a category of products. Many additives within the category have arguably created more harm than good. Now, these terms have no clear meaning.

It is our responsibility to change direction and look to innovative solutions that re-align our industry with best practices. Now is the time to change our thinking about what it means to recycle asphalt waste. The answer is not to abandon RAP usage in asphalt pavements just as continuing the same practices isn’t the solution. The industry must respond by providing superior solutions for RAP restoration so that pavement mixtures demonstrate long-term performance in reliable tests and in the field. We at Blacklidge believe that the responsible thing to do is to upgrade all waste material so that performance is more comparable to – and possibly better than – new asphalt. With the correct approach to recycling, consumption of waste asphalt can reach a level of success previously unseen in our industry.

Our next posts in this series will dive more deeply into the problem and part of our solution, a transformative product platform called ReGen™. I look forward to sharing more soon.

It’s interesting that the current industry standard for asphalt pavement recycling is to allow 20% RAP in a new pavement mixture. This makes me wonder how thoroughly the old material is being integrated with the new material. I would imagine that a quality asphalt recycling service would put more care into making a durable mix. http://renovaindustries.com/

That is nice that asphalt recycling has bee happening for a while. It would be good for someone to get recycling done. That is something I would want to have if I were tearing up asphalt. http://www.hiways.com.au/home/foamed-bitumen-recycling/

Thanks for helping me understand how asphalt pavement recycling works. I’ve been seeing a couple of ads about these lately and my mom wanted me to look it up for her. The idea of restoring a pavement into its original condition is very intriguing. I should share this with her since our pavement has been showing signs of old age. https://blacklidge.com/defining-reclaimed-asphalt-pavement-rap/

Really had no clue what this meant, but now thanks to your great informative article we are fully aware of what this process is like. Appreciate you guys taking the time to share this! Look forward to more articles now. Great stuff.

–Lincoln Concrete Pro’s