It may come as a surprise to you, but asphalt is actually the world’s most recycled material. In 2019 alone, more than 50 million tons of recycled asphalt pavement (RAP) was reportedly stockpiled across the country1. With this abundance, it’s no wonder that cities and municipalities are looking for ways to put RAP back onto their roads.

A Call for RAP Innovation

A study by Texas A&M suggests that “the use of elevated quantities of RAP in low volume roads provide an environmentally responsible solution to the accumulated RAP surplus in some urban areas, while at the same time, offering an economical pavement maintenance and rehabilitation option to local agencies facing budget constraints2.” However, despite the benefits, the study also notes that “elevated quantities of RAP in asphalt pavements present several challenges, such as the variability of the RAP, design methodology and adequate long-term performance.” Therefore, a rejuvenator would be needed to close the performance gap and extend the life of the road.

ReCharge™ Answers the Call …

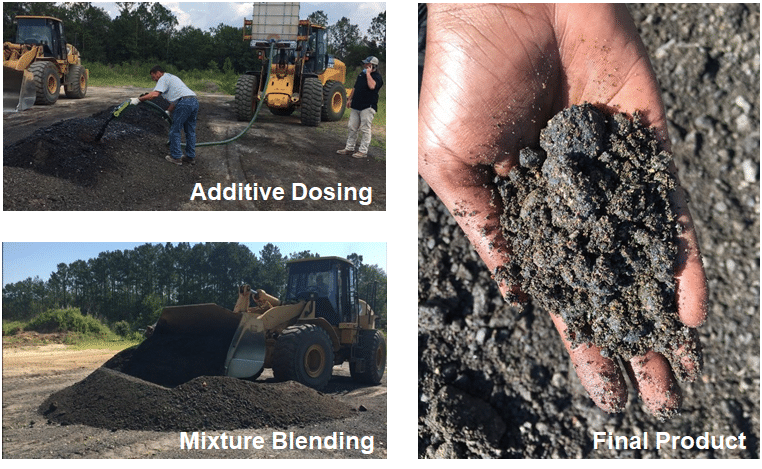

While many rejuvenators require heat and/or new asphalt in the mix, Blacklidge’s ReCharge does not. ReCharge is applied cold, cures quickly and works with 100 percent RAP material — inevitably reducing construction time and costs. Additionally, this product actually activates the aged binder on the surface of RAP. This is a game changer for cold mixes, as the same Texas A&M study observed that they generally do not meet strength requirements and experience accelerated rutting at early load cycles. A few cities and municipalities saw the benefits ReCharge could provide and decided to try the product for themselves to satisfy a variety of objectives.

… in Florida …

Walton County was experiencing severe weathering, wash boarding and potholes as a result of paving with untreated RAP. They needed to pave a residential, 100% RAP road in Santa Rosa Beach using existing RAP stockpile on top of an existing RAP aggregate base. ReCharge provided a cost-effective solution to enhance the pavement’s performance. More than six months after project completion, a field study revealed that the pavement’s performance was holding up — ride quality was good and no rutting or cracking was visible. Some weather and raveling was observed, but was limited to the edges of the pavement. The final result was well-received by Walton County, Charlie Cotton, P.E. of Walton County Public Works stated,

“By mixing milled asphalt with ReCharge, we were able to provide a pavement surface that met all of our needs. The end product has the appearance of a hot mix asphalt surface course and costs a fraction of what a standard overlay costs.”

… in Missouri …

The City of Hannibal wanted to use milled RAP to create a stable base for an asphalt overlay on a low traffic park road. ReCharge was applied to the millings from the pavement to reactivate the asphalt binder and create a new, solid base layer. The city was so pleased with the final result, they even plan to use ReCharge in the future to rehabilitate alleys that have a significant number of potholes.

… and in Mississippi

The City of Ridgeland needed a way to simplify their patch repair while using their existing RAP stockpile on roads with varying traffic. According to Christopher Bryson, Ridgeland’s City Engineer,

“ReCharge drastically reduced our production time and simplified our asphalt mix … We can now have 1 ton of recycled asphalt loaded on the truck within 30 minutes. It used to take over an hour!”

By allowing the city to drastically reduce production time, Ridgeland is now able to fix more potholes than ever before.

The examples provided here are proof that using an advanced cold mix additive, like ReCharge, can maximize RAP use on low traffic roads. From new road construction to ongoing maintenance — ReCharge provides a cost-effective, versatile option that enables cities and municipalities to tap into the real value of their RAP stockpiles.

[1] As reported in NAPA’s Asphalt Pavement Industry Survey on Recycled Materials & WMA Usage (2019)