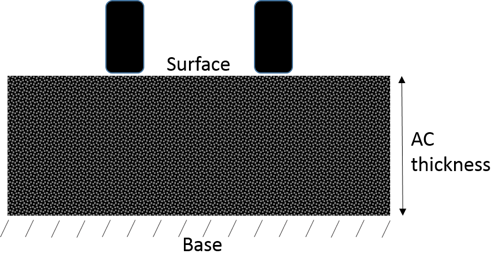

In a land where Pegasus, unicorns, dragons, mermaids, and other mythological creatures exist, asphalt concrete (AC) pavements probably look like this (Figure A):

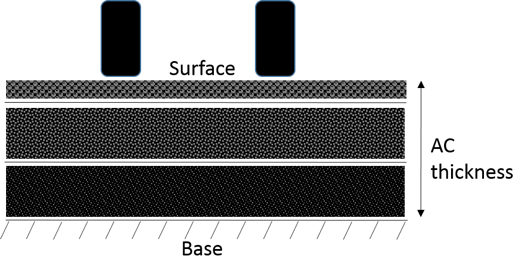

In reality, we live in a world where AC durability, stability, and life-cycle cost are not the only concerns, and in many cases are not even primary concerns. Utility design factors such as driver safety, INITIAL cost, ease of constructability, user-delay, noise, roughness, and optimum use of recycled materials dominate decision-making relative to roadway construction. With all of these considerations in mind, AC pavements tend to look like this (Figure B):

So, why should we be concerned? As shown in Figure B, AC pavements are not monolithic structures – they are pieced together in multiple layers and held with glue. The glue is referred to as the tack coat when applied between AC layers or prime coat when applied directly to the base. This glue is designed to do two things: (1) Keep the different layers from moving parallel to one-another (known as slippage) and (2) ensure that heavy traffic loads are transmitted vertically throughout the depth of the pavement and into the base rather than being concentrated within thinner segmented layers. If the glue fails to accomplish either of these functions, premature failure of the pavement will occur. That’s right—the fate of this pavement structure, in many respects, lies in the quality of the 0.25 mm-thick layer of glue between the layers!

If you have made it this far, you would probably already agree that it doesn’t take a pavement engineer to understand the importance of interlayer bonding in everyday paving practices. Well, as fate would have it, I am actually a pavement engineer who will plainly confirm this as fact. Interlayer bonding has a disproportionately large impact on the outcome. I hate to be the carrier of bad news, but despite this reality, there are still many within this industry who either do not grasp this concept, have not been properly exposed to it, or fail to acknowledge the reality of it. The result? Flawed practices. Flawed pavements. Reduced lifespan. Wasted resources.

There are many essential groups—innovators, material and equipment suppliers, engineers, agencies, road builders, educators, researchers, and tax payers, to name a few—who must contribute for road building to be a success. Superior road building can sometimes be easier said than done, especially when political pressure (one of the most powerful forces in the cosmos) enters into the picture. I have come to accept that simple, logical engineering decisions can become much more challenging when this force is hard at work. Unique insights into how these different groups must continue to navigate the political landscape, adopt a genuine understanding of the tack coat’s functionality, and convert this understanding into superb bond-promoting procedures will become the primary focus of this blog series.

Next in our blog series, how we can fix our problem. Read it here—Interlayer Bonding—Part II: Fixing A Trillion-Dollar Problem