Florida has hundreds of thousands of miles of roads. Today, many of its rural roads remain unpaved. According to the 2018 Florida Department of Transportation’s City and County Mileage Report, there are roughly 18,000 miles of unpaved roads in the Sunshine State.

Historically, dirt roads have been the most cost effective option for low volume roads in many counties and municipalities. However, constituents have reason to complain. With dust and rock chips dirtying and destroying taxpayers’ cars and a bumpy ride that causes a host of problems for vehicles’ shocks and suspension, city and county officials often run campaigns on the promise of “better roads” for their communities.

Regardless of taxpayer complaints and promises from officials to pave dirt roads, government engineers have had no cost effective alternative. However, as recent technological advancements allowed for the successful implementation of high RAP (Reclaimed Asphalt Pavement) contents in asphalt mixtures on low trafficked roads, there’s finally an economical option with environmental benefits. With studies suggesting “the use of elevated quantities of RAP in low volume roads provide an environmentally responsible solution to the accumulated RAP surplus in some urban areas, while at the same time, offering an economical pavement maintenance and rehabilitation option to local agencies facing budget constraints1,” there’s been a considerable shift in rural road asphalt paving.

Florida’s Walton County realized the potential of RAP four years ago and began using almost 100 percent RAP on their less trafficked roadways by compacting untreated RAP on their dirt roads to provide a “paved” surface to their taxpayers. While the RAP mixes provided an economical and environmental benefit, as expected, the untreated RAP allowed for severe weathering, wash boarding and potholes to occur in the “paved” surface very quickly after being put down. So, the county’s quest to make 100 percent RAP roads a functional reality continued.

“The benefits of using reclaimed asphalt pavement (RAP) in asphalt pavements include economics, conservation of natural resources (aggregate, binder, fuel), reductions in energy consumption and decreases in emissions (including greenhouse gases). In contrast, the incorporation of elevated quantities of RAP in asphalt pavements present several challenges, such as the variability of the RAP, design methodology and adequate long-term performance.” 1

In the summer of 2019, Walton County approached Blacklidge for a cost effective, easy-to-implement rejuvenator technology that requires no heat and cures quickly, to be used in their 100 percent RAP surface mixtures to combat the performance issues. Traditionally, rejuvenators require heat or new asphalt in the mix, making additional time and cost inevitable.

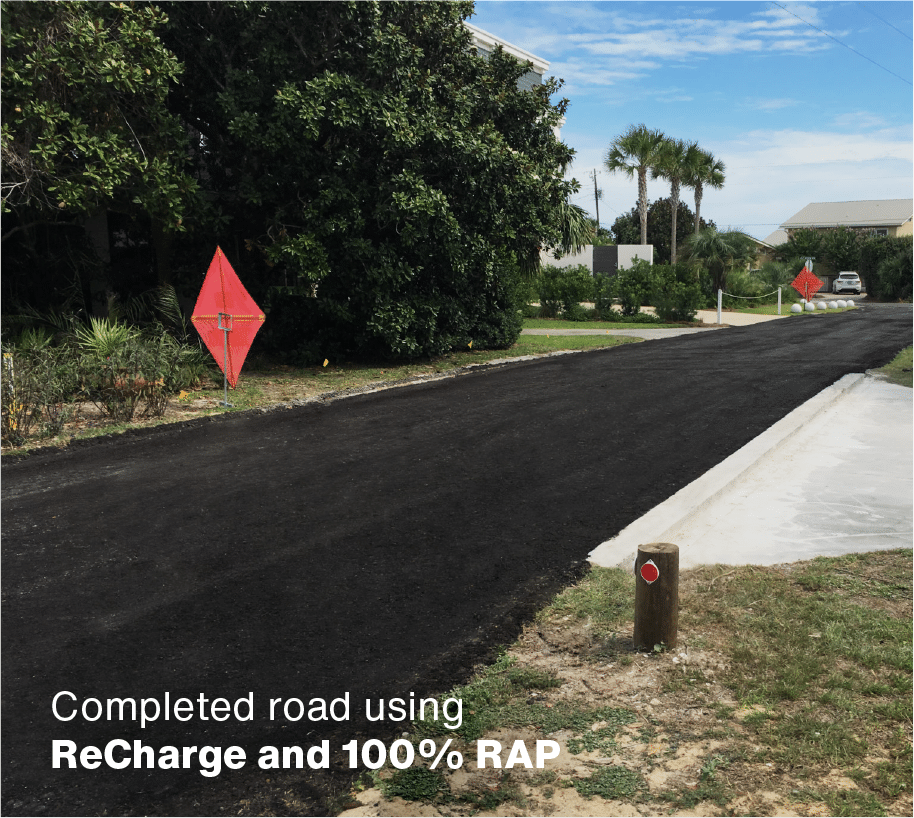

Braxton Gray, South Alabama and North Florida Area Sales Manager at Blacklidge, brought this request to his R&D team. With a product in development that fit the bill, it was time to test its effectiveness in the field. Walton County and Blacklidge added ReCharge™ to the RAP mix on a low trafficked road in August of 2019. The result, according to Charlie Cotton, P.E. of Walton County:

“By mixing milled asphalt with ReCharge, we were able to provide a pavement surface that met all of our needs. The end product has the appearance of a hot mix asphalt surface course and costs a fraction of what a standard overlay costs.”

ReCharge activates aged-asphalt binder already present on the RAP aggregate surface and restores its performance without the need for any heat. The resulting cold mix can be spread onto a surface and compacted similarly to a traditional hot mix asphalt. Within a few hours, the pavement is capable of supporting light traffic. ReCharge provides a cost-effective alternative to unpaved (dirt/gravel) roads, like those described previously in Walton County.

Following the successful implementation in Florida, in March of this year, ATS (Asphalt Testing Solutions & Engineering) published the results of the durability of 100 percent RAP mixtures treated with ReCharge. ATS found that materials treated with ReCharge demonstrated encouraging results from a long-term durability and stability perspective. The Cantabro test performed by ATS was conducted on long-term, oven-aged ReCharge-treated RAP specimens. The end result revealed less than a 10 percent mass loss! This testing confirms ReCharge’s ability to create a durable layer resistant to material loss during the service life of the mix.

“ReCharge got better with age. The durability increased quite a bit. That doesn’t normally happen.” – Tanya Nash, Pavement Materials Engineer, ATS

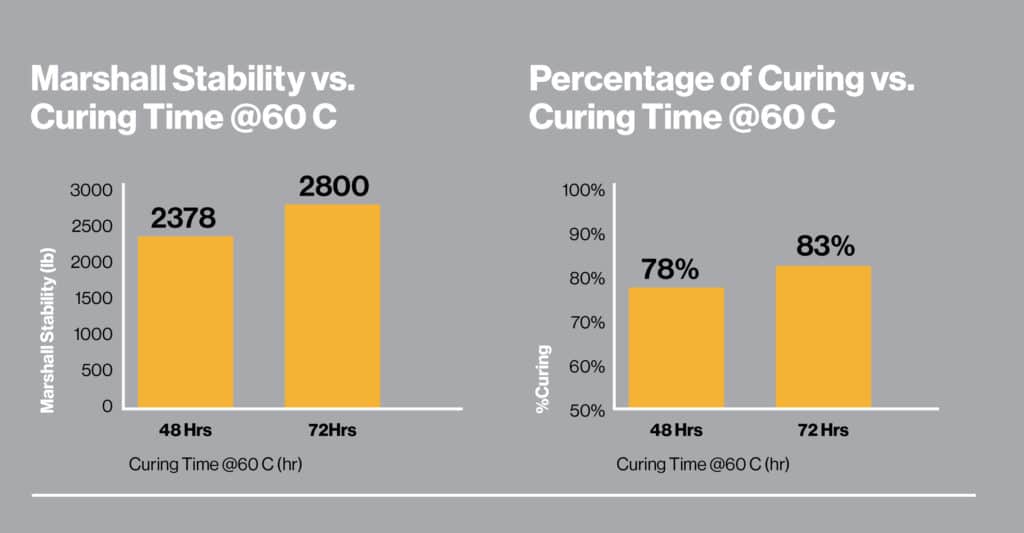

Additionally, a recent study performed by the Delaware Department of Transportation demonstrates ReCharge mix stability as a function of curing time. The graphs below show the measure of Marshall Stability (lb) vs curing time at 60oC as well as the percentage of total curing at 48 and 72 hours. According to these charts, and assuming laboratory conditions, a 100 percent RAP section treated with ReCharge should be able to accommodate repeated light traffic loading in as little as 48 hours as curing continues over time.

And most recently, Dr. Shenghua Wu, assistant professor of civil engineering/pavement engineering at the University of South Alabama, and his engineering students “have been looking for new ways to take that old asphalt, commonly referred to as reclaimed asphalt pavement or RAP, and use it again in effective and cost-efficient ways.” Their study took them to Santa Rosa beach in Walton County, where they conducted a pavement condition survey and extracted core samples from the road originally paved with ReCharge in August of 2019.

“We were checking the asphalt for any distresses such as cracking, rutting (surface depression in the wheel path of the roadway caused by traffic over time), or raveling, which is the aggregate in the asphalt mix that comes loose from the asphalt binder,” said Montalvo, a civil engineering student from Mobile. “The asphalt surface appears to be performing well,” Wu added.

As cities, counties and municipalities face the reality of tighter budgets, they will continue to seek ways to serve their communities in cost effective ways. For rural areas where low-traffic, dirt roads are prevalent, using an innovative, cold-applied rejuvenator like ReCharge — which requires no heat or additional asphalt and enhances the performance of RAP mixes — provides a more economical and environmentally-friendly way to achieve an asphalt pavement.

[1] High Reclaimed Asphalt Pavement (RAP) Asphalt Mixes For Low Volume Roads, Be194, Final Report, November 2018 — Texas A&M Transportation Institute